Modern stainless steel tanks

We have been manufacturing tanks since 1996.

Spomasz Zamość S.A.- A manufacturer of acid-resistant steel tanks,the production of tanks began in 1996. A constantly modernised and upgraded machine park and vast experience in designing tanks makes it possible to manufacture a wide range of tanks, from storage tanks for foodstuff liquids, through technological tanks equipped with heating/cooling systems, mixers, to transport tanks. A wide range of production includes pressure tanks - in this category, bag filters and tanks for storing flammable liquids are manufactured. Spomasz Zamość S.A. is prepared to meet and prove compliance of its pressure equipment with the essential requirements of Directive 97/23/EC. Spomasz holds type approval marks of several storage tanks granted by the President of the Central Office of Measures for tanks for the storage of both alcoholic products and spirits.

Download

Machine park

The plant's equipment enables the precise manufacturing of designed tanks. Among the specialised machines, the following have found their place:

- Spinner for conical bottoms allowing a maximum radius of R100mm,

- Precision-controlled four-roller coiler, with the ability to coil cones,

- CNC plasma cutting machine,

- CNC guillotine shears,

- CNC press brake,

- welding equipment - welding sources with excellent characteristics,

- a system of cranes, hoists and conveyors,

- tank assembly, examination and testing stations,

- internal and external transport.

Assembly and commissioning

We also provide our customers with the opportunity to organise the transport of the products to their destination and a whole range of work related to connecting and commissioning the tanks.

Tank designations

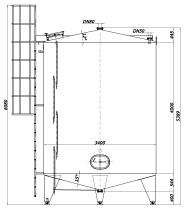

The adopted method of marking tanks is based on letter and number designations, and so the letter designation of the tank characterises its design, while the number designation characterises its dimensions: capacity (m³) and diameter (cm).

For example, ZIW30-300M2³ refers to an insulated tank, equipped with a heating or cooling system, with a capacity of 30m³ and an internal diameter of the tank of 3,000 mm equipped with a vertical paddle agitator.

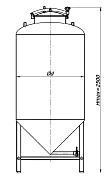

The manufactured tanks can be divided into:

- Storage tanks

- Process vessels

The tanks are manufactured in both vertical and horizontal versions.

Co-financing from ERDF under RDPL

The construction of the tanks is being carried out with machinery purchased as part of the project:

Introduction of innovative automation in the manufacture of machinery used in processing such as tanks - TIG and plasma welding with simultaneous monitoring of the process through SAF VIDEO PROCESS, realised with funds from the European Regional Development Fund under the Regional Operational Programme of the Lubelskie Voivodeship for 2007-2013.

- " Characteristics of acid-resistant steels used in tank construction

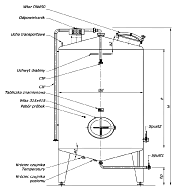

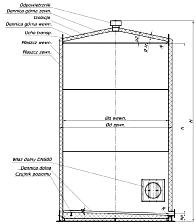

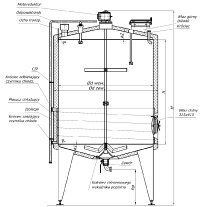

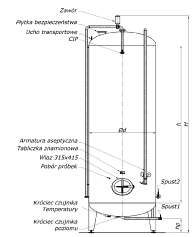

- " Tank equipment

- " Table of tank dimensions

- " Vertical mixers, side mixers

- " GOM 40 washing heads