Chains

General information

Spomasz Zamość S.A. the experienced producer of chains for tens of years. Our chain assortment is wide and fulfils the polish and DIN standards. The chains are produced as temperature processed together with protection layers such as zinc, nickel and acid-proof.

The produced chains are as following:

- drive chains with inches scale from 1" to 4½",

- drive chains with cms scale from 30 mm to 250 mm,

- carrier chains with metric and inches scales, varieties: roll, sleeve, pivot, picker types

We specialize in production the carrier picker chains. We are highly experienced in designing and producing the chains to work in edge temperature conditions. When it comes to the fridge conditions there are the chains in tunnels to produce ice-creams, deep frozen foods; the chains for fridge tunnels to freeze fruit and vegetables. We offer the chains for furnaces to work in immensely high temperatures.

Very high experience and the machine park enable us to produce most of used ladder chains – Gall type.

The chains catalogue

Certificate number

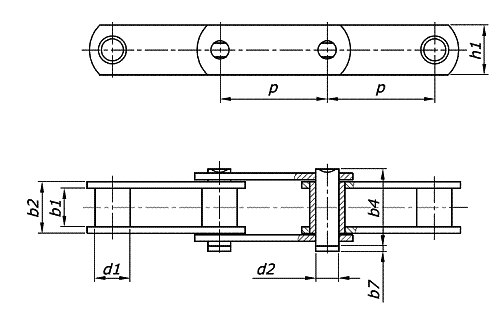

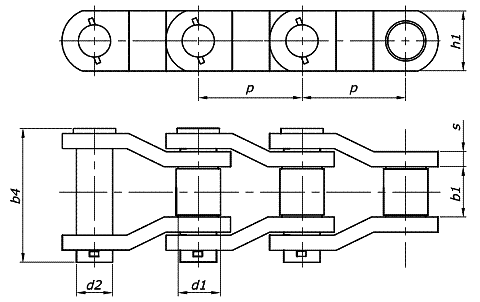

DIN 8187

ISO 606-1994

PN/M-84168

Chain name

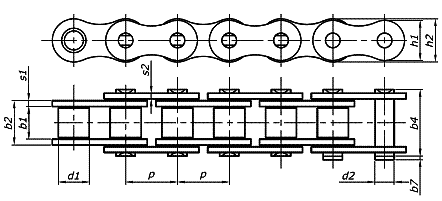

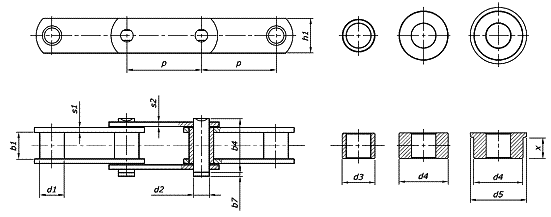

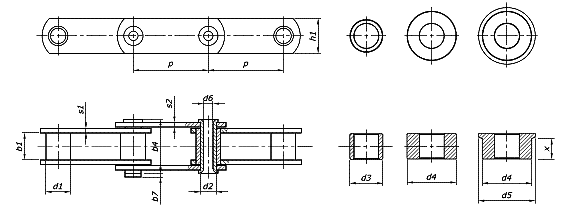

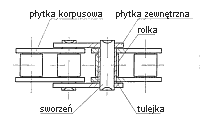

The roller drive chains, precise – one-row type

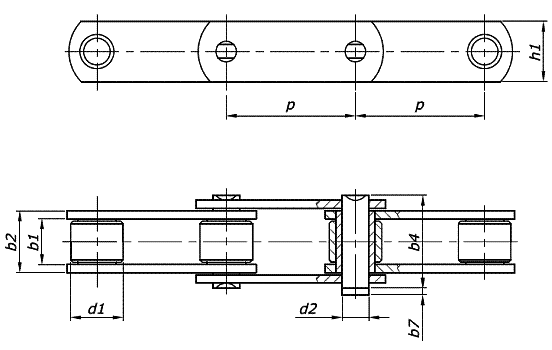

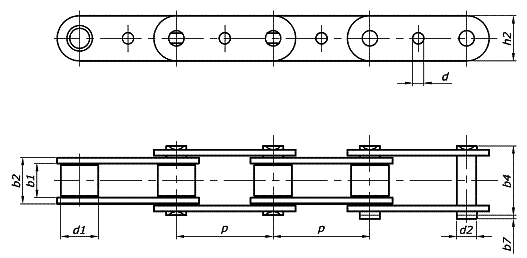

Certificate number

DIN 8187

ISO 606 - 1994

PN/M-84168

Chain name

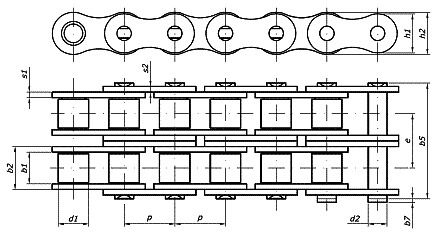

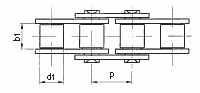

The roller drive chains, precise – two-row type

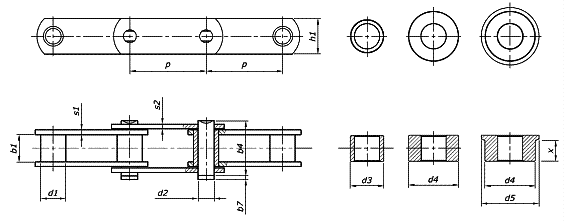

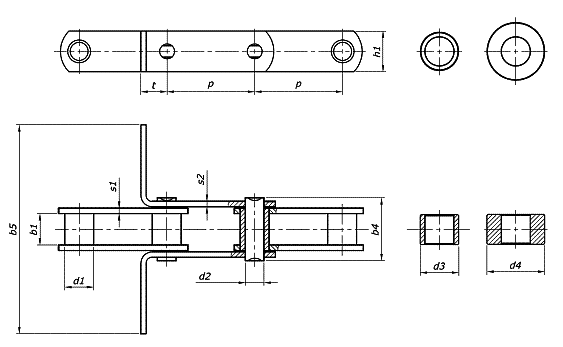

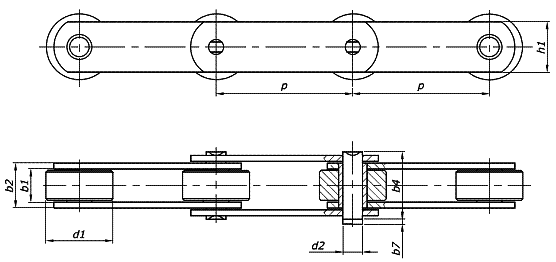

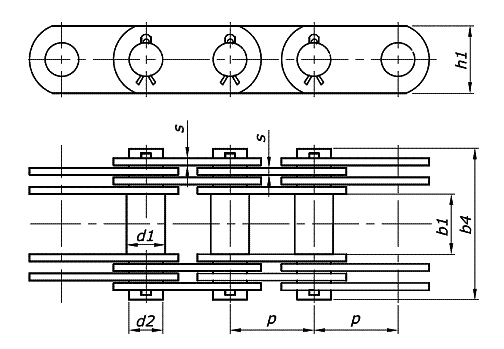

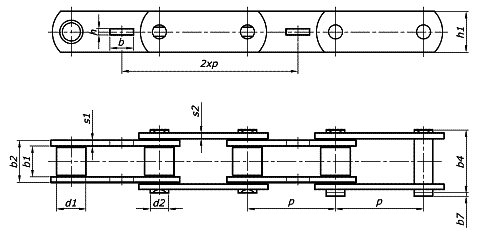

Certificate number

DIN 8187

ISO 606 - 1994

PN/M-84168

Chain name

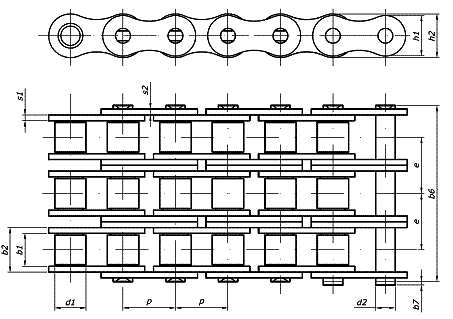

The roller drive chains, precise – three-row type

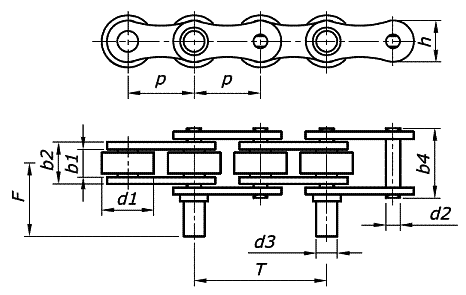

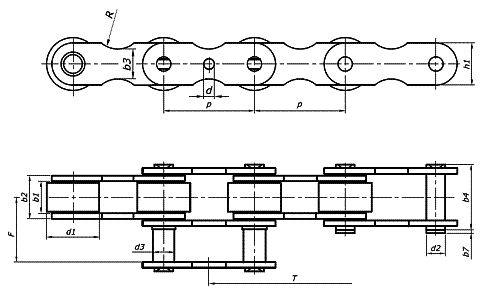

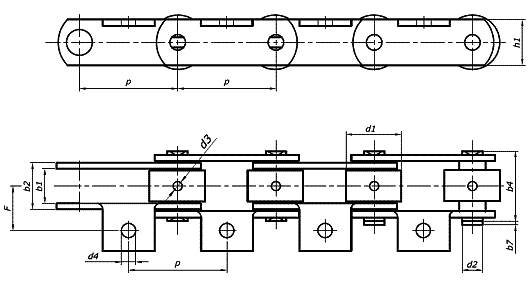

Certificate number

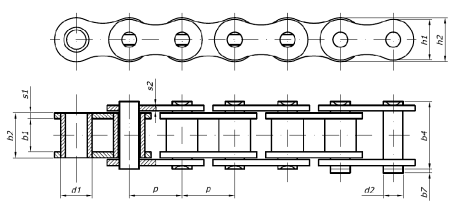

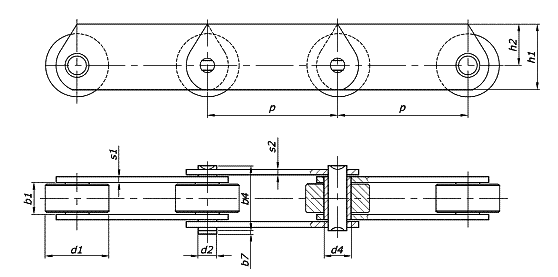

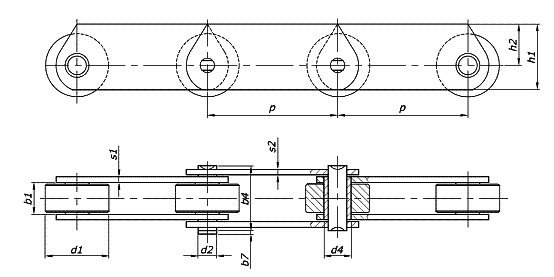

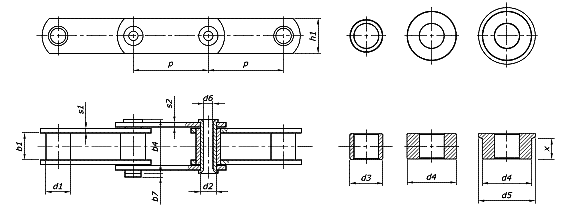

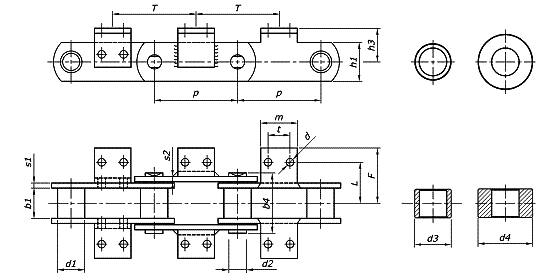

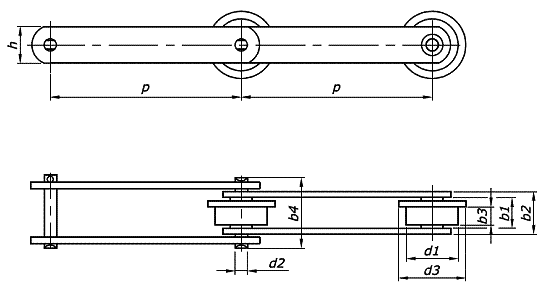

PN-M 84189

DIN 8165

Chain name

Roller pulling chains – chains with the edge rollers

Chains symbol system by Spomasz Zamość S.A.

| item | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| symbol | 50 | C | R | 30 | I | K |

- The digits before the letter symbol means the chain millimeters scale. If the first letter is „C”, the chain scale is defined by inches down and written in millimeters – the example is 50,8mm

- The item meaning is if the chain scale is defined by inches – the letter „C” - or by millimeters – no letter

-

The item identifies the chain type

R - Roller chain

S - Pivot chain

T - Sleeve chain. - The item is the roller diameter. For the inches scale chains [The letter C as the second item] the value is down and is defined in mm. For the metric scale chains the value defines the exact roller diameter.

-

The item defines additional chain parameters

D - bent pickers (welded or riveted)

Da - one-side-bent pickers

E - The taker-board to be welded to the chain

Do - double-side-bent pickers

Dw - pickers bent toward the chain axle

F - The chain with the outer pivot

G - The chain with an additional board

H - Unbent additional pickers

I - The pipe type pivot chain

W - Multi-board chain -

1. The item defines the chain materials type or the layer to cover the chain material type. The lack in the letter means the chain to be made of temperature processed graphite steel.

P - The chain with galvanic or fire-proof zinc layer

K - The chain made of acid-proof steel

Addititional information about chains

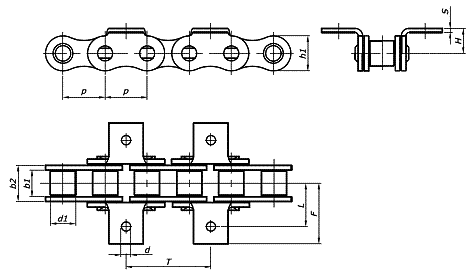

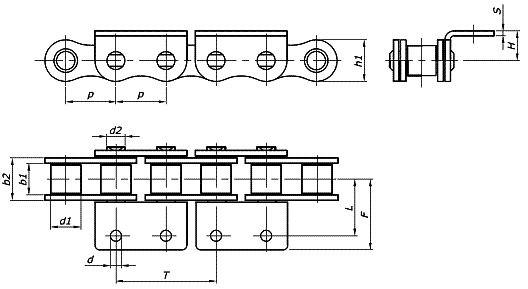

p - chain scale – the distance between the chain pivots

d1 - the roller or sleeve or pivot diameter

b1 - chain inner width – the length between the trunk boards

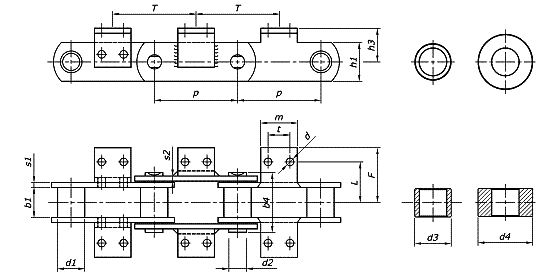

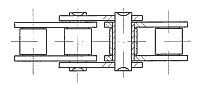

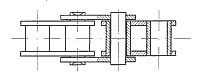

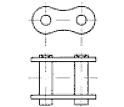

Types of joint links:

clip to be riveted

clip with a cotter pin

clip with a peg

clip with a protective ring

half-clip with a cotter pin

body of chain

Types of links with clamps:

bended clamps, single-sided type Do

bended, double-sided

clamps bended to the inside

welded clamps

clamps straight at one side

clamps straight at both sides

clamps with a protruding pin

chain with an additional plate