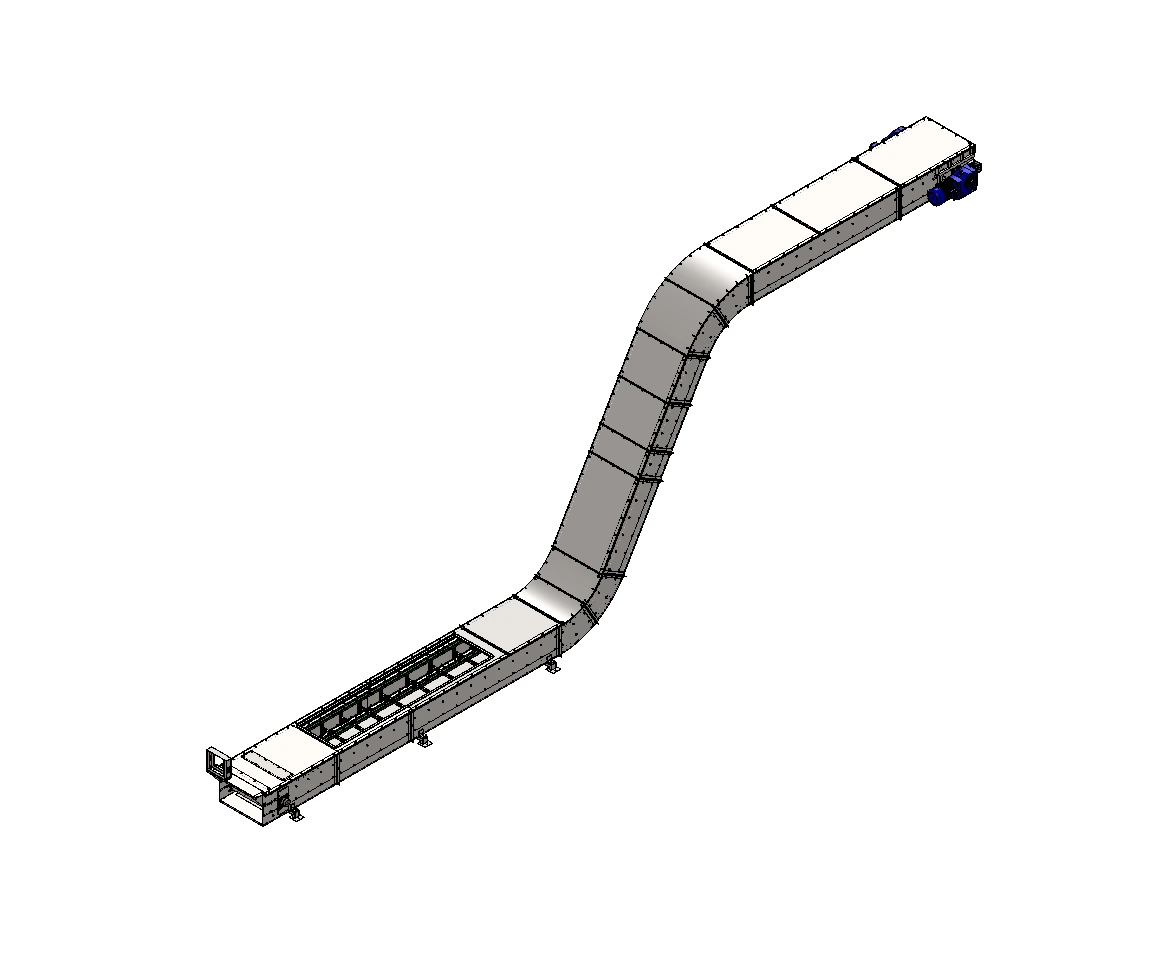

Scraper conveyor redler type PZR

APPLICATION

Scraper conveyors are designed for moving products such as bulk materials, frozen fruit and vegetables, post-processing waste, etc. Depending on the desired performance of the device, the transport chamber (width, height, transport speed) is adapted to the technological needs.

GENERAL CHARACTERISTICS

Scraper conveyors PZR are made as devices in which scrapers transporting the product are moved by chains. The body of the device is placed on a special support structure ensuring transport of the product between two levels. The body of the unit is closed with covers preventing access to the working parts of the unit during operation.

As an option, it is possible to provide opening lids enabling the lifting of the lids for cleaning after the production process. The openable lids are fitted with a sensor that stops operation of the unit if the lid is opened during operation. The bottom part of the trough is fitted with a clean-out cover enabling the removal of product residues from the inside of the trough and the discharge of water after the washing process.

An additional option of controlling the device is the possibility of switching on the "reverse" rotation during the washing process. By switching the appropriate switch, the lids can be opened and the 'reverse' rotation activated. The device may also be equipped with a central 'CIP' washing system consisting of washing heads located inside the body of the device and an electro-valve controlling the washing process.

Both the unit's infeed and outfeed are adapted to the equipment in the production line where the scraper conveyor is located. Depending on the location and the process line in which the machine is located, the geared motor may be fitted with a protective cover. If required, the machine components in contact with the product can be made of austenitic acid-resistant steel and elastomers approved for contact with food products. The conveyor is driven by a geared motor with a power output depending on the size and capacity of the machine.