Pumps for food and chemical liquids

Catalogue of manufactured food pumps

| Pump [Type] |

Capacity [m³/h] |

Lifting height [mH₂O] |

Engine power [kW] |

|---|---|---|---|

| WPs-4 | 3,5 | 5,8 | 0,37 |

| WPs-6 | 6,0 | 10,0 | 0,55 |

| GH-15 | 15,0 | 19,0 | 1,5 |

| GH-20 | 21,0 | 20,0 | 2,2 |

| GH-25 | 25,0 | 22,0 | 3,0 |

| GH-25/4 | 29,0 | 22,0 | 4,0 |

| GH-25/4-160 | 21,0 | 32,0 | 4,0 |

| GA-11 | 8,0 | 11,0 | 0,75 |

| GA-12 | 11,0 | 13,0 | 1,1 |

| GA-13 | 16,0 | 15,0 | 1,5 |

| GA-14 | 19,0 | 20,0 | 2,2 |

| GU-13 | 12,5 | 21,0 | 1,5 |

| GU-14 | 14,0 | 23,5 | 2,2 |

| GU-15 | 18,5 | 46,0 | 6,0 |

| GU-15/4kW | 14,0 | 42,0 | 4,0 |

| GU-30/30 | 30,0 | 30,0 | 5,5 |

| GU-30 | 30,0 | 42,0 | 7,5 |

| GU-46 | 46,0 | 27,0 | 7,5 |

| GU-42 | 42,0 | 50,0 | 11,0 |

| GU-42/60 | 30,0 | 60,0 | 11,0 |

| GU-50 | 47,0 | 30,0 | 7,5 |

| GU-50/15 | 50,0 | 15,0 | 7,5 |

| GU-70 | 68,0 | 45,0 | 15,0 |

| GU-200 | 200,0 | 32,0 | 30,0 |

| GUs30 | 26,0 | 38,0 | 7,5 |

| GUs30/30 | 25,0 | 33,0 | 5,5 |

| GUs42 | 38,0 | 42,0 | 11,0 |

| SPw-11 | 12,5 | 12,0 | 0,75 |

| SPw-12 | 14,0 | 13,5 | 1,1 |

| SPw-13 | 16,0 | 19,0 | 1,5 |

| SPw-14 | 20,0 | 22,0 | 2,2 |

| LR-20 | 20,0 | 22,0 | 7,5 |

| LR-40 | 40,0 | 43,0 | 11,0 |

| GL 13, GL 14 | 12, 14 | 22, 23,5 | 1,5, 2,2 |

Catalogue of manufactured explosion-proof pumps

| Pump [Type] |

Capacity [m³/h] |

Lifting height [mH₂O] |

Engine power [kW] |

|---|---|---|---|

| GH-25Ex | 25,0 | 22,0 | 4,0 |

| GU-30Ex | 30,0 | 42,0 | 11,0 |

Types of positive displacement pumps

| Pump [Type] |

Capacity [m³/h] |

Pressure [bar] |

Engine power [kW] |

|---|---|---|---|

| PWk-10 | 9,0 | 0,5 | 2,2 |

| PWk-12 | 14,0 | 1,2 | 4,0 |

| PWk-36 | 37,0 | 0,42 | 4,0 |

| PWE-40 | 10,0 | 4,0 | 1,5 |

| PWE-50 | 25,0 | 3,5 | 3,0 |

| PWE-65 | 29,0 | 5,8 | 4,0 |

Types of submersible pumps

Subsidised production of centrifugal pumps

We are pleased to announce that

As part of Priority Axis I Entrepreneurship and Innovation of the Regional Operational Programme for the Lubelskie Voivodeship for 2007-2013, Spomasz Zamość S.A. received funding for the project:

"On the basis of currently produced pumps, development and implementation of innovative pumps in explosion-proof execution meeting the requirements of the European Union ATEX Directive 64/9/EC" specified in the application for funding of project implementation no. 02.11-WND-RPLU.01.03.00-06-098/11

As part of the grant received, two new types of centrifugal pumps were launched and put into production:

Type GH25Ex centrifugal pump for use in potentially explosive atmospheres, as a monobloc including motor and seal protection against working fluid leakage and overheating.

Type GU30Ex centrifugal pump for use in potentially explosive atmospheres, as a monobloc including motor and seal protection against working fluid leakage and overheating.

As part of the modernisation of manufactured products, the following were carried out:

- upgrade of GH and GU pumps to operate under negative pressure on the inflow side

- Upgrading of the GH and GU pumps involving the construction of a pump heating jacket.

To download

SPOMASZ Zamość S.A. is a manufacturer of centrifugal pumps used in the food industry called Food Pumps.

35 years of experience in the manufacture of centrifugal pumps for the food industry.

It all started with the purchase of a licence for the production of GA type pumps.

GA centrifugal pumps have been known by our customers since the 1970s. Formerly known as 'milking machines' and often referred to nowadays as the most reliable pumps.

Today, SPOMASZ Zamość S.A. is a

Manufacturer

- Eight types of centrifugal pumps, each in several sizes

- One type of positive displacement lobe pump

- One type, in two sizes, of the LR circulating centrifugal pump, known as the CIP minus or CIP return pump.

Reliable partner

- Providing assistance in selecting a pump for the application

- Responding to changing market demands for centrifugal pumps

- Supplying pumps to several hundred demanding customers at home and abroad

- Fulfilling 'catalogue' orders within one week

Why SPOMASZ food pumps?

- The pumps meet all requirements for equipment in food applications

- They have a sturdy construction built from high quality materials

- They are safe, durable, economical and reliable in operation

- All spare parts are available from stock and "off-the-shelf"

- Warranty and post-warranty service with fast response times.

Food pumps are pumps designed to be used in food industry applications. The special features of SPOMASZ Zamość S.A. food pumps are:

- Material execution from acid-resistant steel, cold-rolled sheet metal, grade 1.4404

- Internal surfaceroughness <0.8µm and in special cases 0.4µm

- Mechanical seals used (internal and external) designed to ensure hygiene in the process and cleaning of the pump in the CIP circuit

- The design of the pumps eliminates the possibility of dead zones - nooks and crannies that are difficult for cleaning agents to reach.

- The bodies of the new pumps are made using cold-stamping technology with 6.0 mm-thick plates, which guarantees the pump's stability under varying load conditions and influences the durability of the mechanical seals.

The choice of materials for inert-gas shielded welded joints and the treatment of non-separable joints eliminates the formation of potential differences at the material boundaries. - Pump impellers - in most models (except the GA pump) of open construction, cast in chromium-nickel steel using a method that allows them to be machined to the declared roughness. All impellers are statically balanced, which increases the life of the pump.

- Process connections

Hygienic connections are standard, ensuring both easy installation of the pump into the system and a safe connection, made in accordance with DIN 11851.

On request, the pumps can be fitted with SMS, Tri-Clamp or DIN flange connections. - Motors

Two-pole 50Hz AC electric motors are the standard installed in pumps.

The motors are fitted with bearings to compensate for any axial movement of the shaft and a special motor shaft end - made of acid-resistant steel, which is also the pump shaft.

All motors installed in SPOMASZ pumps meet the requirements for operation in a high-moisture environment and are resistant to splashes when washing the equipment from the outside. In addition, each pump has a specially designed motor cover, providing additional protection. - Modern design of the new pump line initiated by the WPs pump design and continued in the GU30/30, GH, GU15 pumps

- Testing, certification

Each pump type is tested by an independent laboratory for safe operation. Each pump is clearly identified and bears the CE safety mark.

All pumps have been tested by the National Institute of Hygiene for human health hazards. Each pump has a Certificate of Health Quality (PZH Certificate)

The aforementioned specialfeatures of the food pumps manufactured at SPOMASZ Zamość S.A. result in the following.

- The media pumped through them do not change their properties or structure during the process of pumping the process media

- The CIP, SIP processes carried out in installations where SPOMASZ pumps have been installed are achieving the desired results.

Application of SPOMASZ food pumps

- milk pumps, cream pumps, ice cream pumps,

- animal blood pumps, brine pumps,

- pumps in brewing, beer pumps, wort pumps, extract pumps,

- juice pumps, beverage pumps, water pumps,

- tomato juice pumps, apple juice pumps, orange juice pumps,

- nectar pumps, honey pumps, mead pumps,

- wine pumps, alcohol pumps, spirit pumps, mash pumps,

- pumps for royal jelly, pumps for liquid yeast,

- pumps for injectable fluids, pumps for pharmacy,

- cold water pumps, hot water pumps, chilled water pumps,

- CIP pumps, washing pumps, CIP return pumps, draw-off pumps,

- lye pumps, acid pumps, sanitisation pumps.

We hope that the material presented will give you an idea of the range and applications of the food pumps produced, which are also intended for the cosmetics industry, pharmaceuticals and household chemical manufacturers.

Basic pumping issues for centrifugal pumps

A centrifugal pump, or more precisely a rotodynamic pump, is a device in which the rotating impeller transfers to the liquid the energy received from the motor, causing the liquid to spin and rise (increase in pressure), thus creating a suction effect at the pump's inlet.

Vortex pumps differ from positive displacement pumps in that a positive displacement pump pressurises at a pressure allowed by the size of the drive installed in the pump - with a practically unchanging capacity, whereas a vortex pump pressurises at a capacity allowed by the size of the drive installed in the pump - with a decreasing head.

Pump capacity (Q)

This is the volume of liquid pumped per unit time. Pump capacity is usually expressed in m³/h or L/min

Head (H)

This is a parameter characterising centrifugal pumps - which convert the velocity energy of the liquid into position energy, i.e. height, and is expressed in metres of water column [mH2O].

Power requirement (P)

This is the power consumed by the pump during operation.

Speed (n)

This is the number of revolutions of the pump shaft in one minute [rpm].

Pump efficiency (η)

This is the ratio of the pump's useful power to the power consumed by the pump at the shaft and is expressed in [%]. With a high-efficiency pump, the efficiency reaches higher values compared to a low-efficiency pump.

Suction capacity

Centrifugal pumps have an open construction - the pump's rotating parts do not come into contact with each other - which makes it easier to keep the pump clean, but prevents the pump from sucking in liquid. Centrifugal pumps should be installed so that they operate with the liquid flowing through them (the suction port in the pump should be below the surface of the liquid being drawn in).

When selecting a pump for a system, care should be taken to ensure that it will operate at a capacity that the pressure in the discharge line will allow. It is a good idea when the pump operating point (Q,H) corresponds to the maximum efficiency of the pump. When the capacity exceeds the maximum values, the power requirement of the pump increases and cavitation may occur on the suction side of the pump and in the pump. When the capacity is reduced to zero, e.g. due to an increase in resistance on the discharge side, there may be a phenomenon of heating of the liquid in the pump casing.

Handling heavy liquids

The pumping of liquids with a specific weight higher than that of water does not have the effect of lowering the pump head, but only increases the energy consumption of the pump - due to the pressure exerted on the pump impeller blades. However, it is very often the case that liquids with a higher specific weight also have an increase in viscosity.

Handling viscous liquids

Handling liquids with viscosities higher than those of water will reduce the pump's performance, i.e. flow (Q) and head (H), while significantly increasing the power required to drive the pump (P) due to the need to overcome the internal friction resistance of the liquid and the impeller and internal pump components.

When pumping liquids with viscosities much higher than those of water at full throttle, the liquid head is close to the head specified for water. As the pumped liquid capacity increases, there is a significant drop in the pump head.

A comparison of the characteristics is possible on the basis of nomograms that determine the drop in pump performance as a function of the viscosity of the liquid being pumped, its flow rate and head.

Effect of varying the frequency of the current feeding a three-phase motor on its speed

, where f- current frequency[Hz], p- number of pole pairs (3000 rpm motor = 1 pole pair), n- motor speed [rpm].

, where f- current frequency[Hz], p- number of pole pairs (3000 rpm motor = 1 pole pair), n- motor speed [rpm].

The motor speed is 1.5-3.5% lower than the magnetic field speed calculated in this way

Effect of varying the pump speed (n) on the capacity, head, power requirement of the pump (Q, H, P)

Effect of changing the pump impeller diameter (d) on the capacity, head, power requirement of the pump (Q, H, P)

Centrifugal pump type WPs

The pump is used for all liquids used in the food industry where there is low system pressure and low capacity and head is required.

Pump type GH

The pump is designed for installations where food safety is very important

Transport of liquid food products with viscosity up to 1000 cP,

the pump is used in:

- dairy (fresh and pasteurised milk, whey, ice cream mixes)

- fruit and vegetable processing (non-clarified and clarified juices),

- pharmacy

Pump type GA

A classic pump used in dairy installations for several decades. Reliable in operation, its design and the shape of the internal casing contribute to the long life of the mechanical seal.

The pump is the only centrifugal pump made of AISI 304 steel in the food pump range. All other pumps are made from AISI 316L (1.4404) stainless steel. The pump is fitted with a closed impeller.

Pump type GU13 and GU14

The pumps are designed for the transport of concentrated foodstuff liquids with a dry-matter content of up to 50% or other foodstuff liquids with similar properties at temperatures of up to 95°C.

The pump is fitted with an open impeller. Equipped with a classic soft graphite seal, the pump can operate in installations with low vacuum.

Pump type GU15 and GU15/4

The pump is designed for conveying non-concentrated or concentrated food liquids with a dry matter content of up to 50% or other liquids with similar properties at temperatures of up to 95°C.

Due to the increased head, it can be used for pumping media through plate and tube heat exchangers and other devices with considerable resistance.

Pump type GU-30/30, GU-30, GU-50/15, GU-46, GU-42, GU-42/60, GU-50, GU-70

A range of centrifugal pumps designed to feed foodstuffs with viscosities up to 1000 cP.

- dairy (fresh and pasteurised milk, whey, ice cream mixes)

- fruit and vegetable processing (non-clarified and clarified juices, juices with fibres, fruit drinks, vegetable drinks, wines, liqueurs),

- distilling (distillery mash, spirits)

- pharmacy

- pumping of basic utilities in the food industry (water, cold or hot purified water

- cleaning fluids for the CIP system and other fluids.

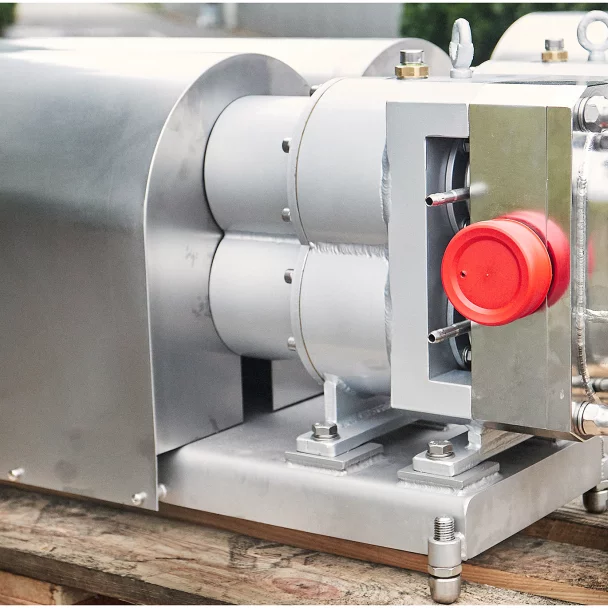

Pump type PWk

Lobe pump with adjustable cam speed.

A type of positive displacement pump, it is used for pumping liquids with high viscosity (up to 10,000cP)

Mayonnaise, ketchup, concentrates, oils, processed cheese, yoghurt. The pump has the ability to pump soft solids without crushing them.

CIP return pump type LR

Circulating centrifugal pump.

The pump is not a product pump, it is used in cleaning installations in the CIP circuit.

The pump has a high suction capacity of approx. 7 mH₂O and the ability to self-prime the liquid due to the annular channels in which the liquid permanently remains.

Dynamic agitator type MD

Mechanical mixer designed for mixing several streams of liquids in a flow.

The device is capable of effectively mixing liquids that react aggressively with each other under ambient conditions - forming gels or releasing significant amounts of temperature during the mixing process.

The manufactured varieties of dynamic mixers are designed for mixing two liquid components or three liquid components.

The four-rotor agitator - Homogeniser type H4 is designed for homogenisation of liquids prone to sedimentation.