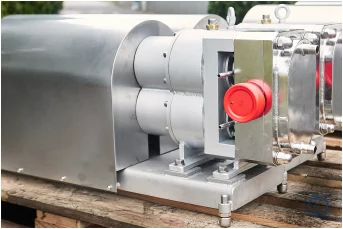

Positive displacement pumps for concentrated food liquids Type PWk-12 and PWk-12V

General information

The PWk12 pump is characterised by its horizontal drive arrangement.

The PWk12V pump is characterised by its vertical drive arrangement, which significantly reduces the length of the pump-motor combination.

To download

Use for pumping

Dairy industry

Manufacture of yoghurt (also with fruit pieces), cream, cottage cheese.

Food industry

Mayonnaise, jams, preserves, sauces, fruit pulp, and liquefied fruit in pieces.

Yeast milk, filling, liquid stuffing,...

Chemical industry

Viscous solutions of soaps, shampoos, creams, emulsions, soap and cosmetics.

Confectionery industry

Vegetable and animal fat, toppings, caramel.

General characteristics

The pump is designed for pumping viscous liquids in the food industry and liquids that must be handled gently and gently during the pumping process. This is made possible by the low speed of the cams.

The pump casing is fitted with two DN50 connecting nipples to DIN 11851. The casing is made of stainless steel to EN10088 marked 1.4404 (AISI 316L).

The product is transported in the space formed by the precision-made cams and the pump body. Each cam has a separate drive from the gearbox; the precision of the gears and cams ensures that the cams do not come into contact with each other and with the casing and end walls. The minimum clearances take into account the effects of the temperature of the pumped medium so as not to cause seizure of the working elements of the pump. The precision of manufacture also preserves the roughness parameter, which internally does not exceed Ra0.8um.

The pump shafts are sealed with mechanical seals on the cam side and with simulators on the gland flushing water side. When gland flushing is not required, we simply do not connect water to the tubes feeding the gland seals. The mechanical seal is lubricated on the side of the pumped medium and the simulation does not require lubrication.

Seal material sets to be agreed at the bidding stage.

The pump casing is connected to a gearbox made of carbon steel with corrosion protection. The gearbox is fitted with two toothed wheels mounted on expansion sleeves, which makes it easy to adjust the position of the cams after bearing replacement or other service work during operation.

The gearbox is connected by means of a clutch to a geared motor integrated into the motor. The pump uses a motor to cooperate with an inverter controlling the pump's rotation in 87 Hz technology, which is included in the pump's scope of supply, enabling precise selection of pumping parameters. Drive cover included

Characteristic of this type of pump is that the suction port, when the direction of rotation of the cams is changed, becomes the discharge port and the discharge becomes the suction port. The direction of rotation can be changed.

Technical specifications

| Parameter | Unit | PWk-12 | PWk-12V |

|---|---|---|---|

| Capacity max. | [m³/h]. | 14,0 | 14,0 |

| Outlet pressure max. | [MPa] | 1,2 | 1,2 |

| Temperature of pumped liquid | [°C] | 95 | 95 |

| Engine power | [kW] | 4,0 | 4,0 |

| Nominal speed at 87Hz | [min-1]. | 534 | 534 |

| Nominal speed | [min-1]. | 307 | 334 |

| Gearmotor type | - | SK571.1-112MP/4TFF | SK93372.1VX-112MP/4FTF |

| Supply voltage | [V] | 400 | 400 |

| Rated current | [A] | 7,85 | 7,85 |

| Mass | [kg] | 150 | 155 |

Overall dimensions of the PWk-12 pump

Overall dimensions of the PWk-12V pump

Features of the PWk-12 and PWk-12V pumps